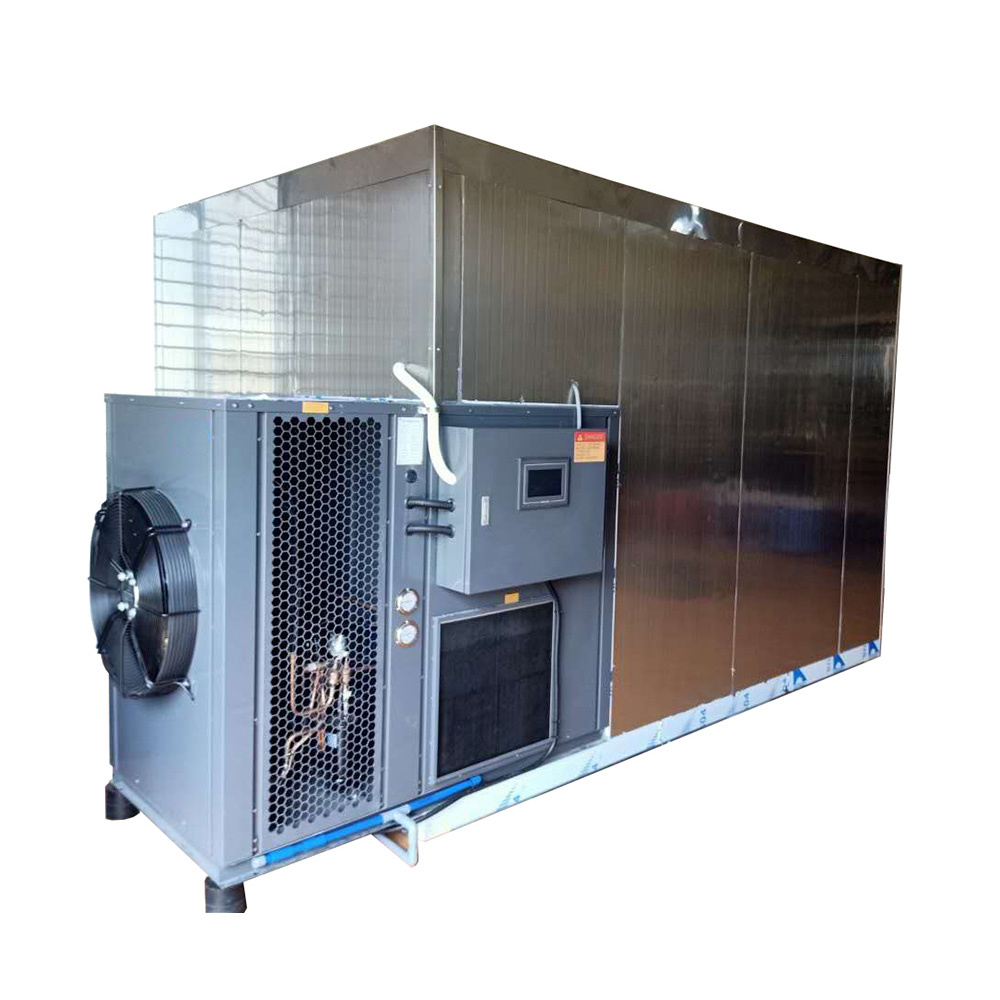

CE Certified Industrial Food Dehydrator – Multi-Purpose Dryer for Beef Jerky, Vegetables, Seafood & Fruits

The MeiYa CE Certified Industrial Food Dehydrator is a high-performance solution designed for commercial-scale dehydration of beef jerky, vegetables, seafood, fruits, and more. Combining advanced heat pump technology, precision drying controls, and CE-certified safety standards, this system delivers energy savings, nutrient retention, and compliance for global food processors.

Core Innovations & Technology

1. Multi-Purpose Drying Capabilities

• Beef Jerky: High-temperature cycles (60–75°C) eliminate pathogens while preserving protein integrity, meeting USDA and EU food safety standards. • Vegetables & Fruits: Low-temperature drying (35–55°C) retains 95% of vitamins (e.g., vitamin C in peppers, folate in spinach).

• Seafood: Uniform dehydration of shrimp, fish, and squid at 50–65°C to achieve <8% moisture, extending shelf life for export.

2. Energy-Efficient Heat Pump Technology

• Closed-Loop Heat Recovery: Recycles 85% of thermal energy, reducing energy consumption by 60–70% compared to traditional dryers.

• Solar-Ready Design: Optional integration with renewable energy systems to align with EU Green Deal 2030 sustainability goals.

3. Precision Control & Hygiene

• Smart Touchscreen Interface: Pre-programmed settings for 20+ food types with real-time adjustments for temperature (±1°C) and humidity (±3% RH).

• Easy-Clean Stainless Steel Trays: Smooth surfaces simplify sanitation, complying with FDA 21 CFR Part 117 hygiene protocols.

4. Scalable Power Options

• 5.5KW Model: Ideal for SMEs.

• 9.5KW Model: Mid-scale operations.

• 19.4KW Model: Industrial-grade capacity.

Key Features

✅ CE & ISO 9001 Certified: Compliant with EU safety and quality standards.

✅ Uniform Airflow Design: Eliminates hotspots for consistent drying across all trays.

✅ 12-Month Warranty + Lifetime Support: Comprehensive after-sales service and technical assistance.

Applications & Workflow

Beef Jerky Production

- Marination & Prep: Slice meat uniformly for even drying.

- High-Temp Drying: Set to 70°C for 6–8 hours to ensure pathogen-free jerky.

- Packaging: Achieve <10% moisture for shelf-stable, ready-to-sell products.

Vegetable & Fruit Drying

• Leafy Greens: Dry kale or spinach at 40°C to retain nutrients for health snacks.

• Tropical Fruits: Preserve mangoes and pineapples at 50°C for vibrant color and natural sweetness.

Seafood Processing

• Shrimp: Dehydrate at 55°C for 4–6 hours to lock in flavor and texture.

• Fish Fillets: Optimize drying cycles to meet Japanese and EU import standards.

Technical Specifications

• Temperature Range: 30–80°C

• Capacity: 100 kg–10 tons/day (modular)

• Power Options: 5.5KW / 9.5KW / 19.4KW (380V/50Hz)

• Certifications: CE, ISO 9001, FDA

Market Advantages

✅ Cost Efficiency: Achieve ROI in 12–18 months through energy savings and reduced waste.

✅ Global Compliance: Export-ready for EU, North America, and Asia-Pacific markets.

✅ Versatility: Switch between beef, seafood, and produce without downtime.

Success Stories

• Beef Jerky Manufacturer (Texas, USA): Increased production by 300% while cutting energy costs by 50%. • Vegetable Processor (Spain): Supplied ISO-certified dried tomatoes to EU supermarkets, reducing spoilage by 40%. • Seafood Exporter (Vietnam): Met Japan’s strict <8% moisture requirements for dried squid, doubling export revenue.

Why Choose MeiYa?

• 12+ Years of Expertise: Trusted by food processors in 50+ countries.

• Custom Solutions: Tailor drying cycles, tray layouts, and energy sources to your needs.

Transform Raw Ingredients into Profitable, Shelf-Stable Products

From protein-rich jerky to nutrient-packed snacks, MeiYa’s CE-certified dehydrator ensures quality, efficiency, and compliance.

📧 Contact us today for a free drying trial or customized quote!

MeiYa Heat Pump Dryer Machine

- No MOQ & Customization Unlimited

- Drying + Dehumidify + Cooling

- PLC + Touch Screen Control

- 7-10 Days Delivery Time

Parameter:

| Single dryer+drying chamber | ||||

| Model | Unit | MY-03RD | MY-06RD | MY-12RD |

| Power input | KW | 5.5 | 9.5 | 19.4 |

| power supply | V/PH/HZ | 380V/3PH,50/60HZ | 380V/3PH,50/60HZ | |

| 220V/1PH,50/60HZ | ||||

| Rated current | A | 9.6A(380V),22A(220V) | 17.0 | 30.0 |

| Heating capacity | KW | 10.5 | 21.0 | 42.0 |

| Cooling capacity | KW | 7.8 | 18.0 | 32.0 |

| Dehumidity | L/H | 12.0 | 25.0 | 50.0 |

| Max temperature | ℃ | ≤75 | ≤75 | ≤75 |

| Working condition | ℃ | 0-43 | 0-43 | 0-43 |

| Electric shock protection grade | 1 | 1 | 1 | |

| Max exhause pressure | M(P)a | 30 | 30 | 30 |

| Noise | d(B(A | 75 | 75 | 75 |

| Power consumption/H | KWH | 4.8 | 8.5 | 15.0 |

| Electric heater | KW | 3.0 | 6.0 | 12.0 |

| Blowing type | / | HORIZONTAL BLOWING TYPE | ||

| Demsnssion of dryer | MM | 3160*2070*2200 | 5700*2170*2200 | 5810*3230*2200 |

| Weight | KG | 180 | 285 | 480 |

Buying Guiding:

Recommend drying machine+Drying chamber sizes

| ITEM | DESCRIPTION | PRODUCT CAPACITY | DRYING CHAMBER SIZE |

| 1 | One unit MY-03RD+Drying chamer | 300/batch | 4000*2000*2200 |

| 2 | One unit MY-06RD+Drying chamer | 600/batch | 6000*2800*2200 |

| 3 | One unit MY-12RD+Drying chamer | 1300/batch | 6000*3000*2200 |

| 4 | Two unit MY-03RD+Drying chamer | 1200/batch | 7000*2200*2200 |

| 5 | Two unit MY-06RD+Drying chamer | 1500/batch | 10000*2800*2200 |

| 6 | Two unit MY-12RD+Drying chamer | 3500/batch | 10000*3000*2200 |

Our Projects:

Our Factory:

Production Processing:

Drying Machine Components:

Standard Working Modes:

- Typically 3 modes available:

- Drying Only

- Rapid temperature rise; unable to discharge moist air

- Drying + Dehumidify

- Chamber temperature rises while discharging moist air

- Cooling

- Temperature can drop to 10°C (minimum)

- Important Note:

- If temperature control becomes unstable, switch to Temperature & Humidity Mode.

- Drying Only

Drying Machine Common Issues

- Q1: High Pressure Protection

- A1.1: Hot air circulation system failure

- AC contactor overload protection

- (Check phase loss/loose terminals/voltage instability)

- Partial fan failures

- (Verify switches configuration and burnt components)

- Mechanical fan damage

- (Replacement or removal required)

- AC contactor overload protection

- A1.2: Tray overloading phenomenon

- Optimal spacing: 8-10cm between trays

- (Causes airflow obstruction in drying chamber)

- Optimal spacing: 8-10cm between trays

- A1.3: Electronic expansion valve anomalies ▪ Automatic minimum aperture adjustment

- (Sensor calibration: Reposition or exchange Sensor 1/2) ▪ Valve body malfunction

- (Manual rotation intervention needed)

- (Sensor calibration: Reposition or exchange Sensor 1/2) ▪ Valve body malfunction

- A1.4: Chamber overheating condition

- (Temperature parameter adjustment solution)

- A1.5: Refrigerant specification error

- (High-temperature type gas recharge required)

- A1.1: Hot air circulation system failure

- Q2: Low Pressure Protection

- A2.1: Gas leakage scenario

- (Leak detection and repair protocol)

- A2.2: Extreme cold environment

- (Extended check intervals or R22/R417A refill)

- A2.3: Valve aperture deficiency

- (Expansion valve opening adjustment method)

- A2.1: Gas leakage scenario

- Q3: Exhaust Temperature Overload

- A3.1: Gas leakage recurrence

- (Refers to Q2.1 resolution process)

- A3.2: Valve operational failure

- (See A1.3.2 corrective action)

- A3.1: Gas leakage recurrence

- Q4: Sensor Malfunction

- A4.1: Temperature sensor defect

- (Replacement procedure guidelines)

- A4.1: Temperature sensor defect

- Q5: Moisture Evacuation Failure

- A5.1: Dehumidification fan damage

- A5.2: Control system malfunction

- A5.3: Power delivery irregularity

Our Services

A. Payment Service

- T/T (Telegraphic Transfer)

• Applicable to all transaction types. - L/C (Letter of Credit)

• Exclusively available for container orders. - Western Union

• Recommended for sample orders and spare parts procurement.

B. Technical Service

- Capacity Analysis & Model Recommendation

• We provide customized capacity calculations and optimal model selections based on operational requirements. - Professional Technical Support

• Comprehensive refrigeration and electronic engineering assistance for installation, debugging, and system operation. - Spare Parts & Post-Warranty Support

• Genuine spare parts and technical guidance provided during and after the warranty period. - Training Programs

• On-site or factory-based training courses available upon request.

C. After-Sales Service

- Technical Assistance

• Continuous support for installation, operation, and maintenance. - Warranty Policy

• 12-month warranty coverage with optional extension. - Cost-Effective Post-Warranty Support

• Spare parts and technical services offered at competitive rates after warranty expiration.