Commercial Multi-Function Food Dehydrator for Fruits, Vegetables, Herbs & Rose Petals – Energy-Saving Drying System

The MeiYa ProDry 2025 is a state-of-the-art commercial dehydrator engineered for high-efficiency processing of fruits, vegetables, herbs, and delicate floral materials like rose petals. Combining precision drying technology, adaptive energy management, and hygienic design, this system reduces energy consumption by 50–70% while preserving color, flavor, and bioactive compounds, meeting global standards for food safety and sustainability.

Core Innovations & Drying Excellence

- Adaptive Heat Recovery Technology

• Closed-Loop Energy Recycling: Inspired by industrial-grade heat recovery systems, the ProDry recycles 85% of waste heat from exhaust air, drastically cutting energy use compared to conventional dryers.

• Multi-Stage Drying Protocols: ◦ Fruits (e.g., Apples, Mangoes): Low-temperature cycles (40–55°C) retain 95% of vitamin C and natural sugars, ideal for snacks or freeze-dried ingredients.

◦ Herbs & Rose Petals: Gentle drying at 30–45°C preserves 90% of volatile oils (e.g., geraniol in roses) and antioxidants for cosmetics and herbal teas.

◦ Vegetables (Carrots, Kale): High-efficiency airflow ensures uniform moisture removal (<10%) while maintaining crisp texture. - Intelligent Drying Control

• Microcomputer PID Temperature Control: Adapted from industrial drying systems, this feature maintains ±1°C accuracy, preventing over-drying and energy waste.

• Real-Time Monitoring: A 10-inch LCD touchscreen displays humidity (10–85% RH), temperature, and energy consumption, with pre-programmed settings for 20+ food types. - Hygiene & Safety

• Self-Cleaning Function: Automated sanitation cycles reduce cross-contamination risks between batches.

• Overheat Protection: Automatically cuts power if temperatures exceed safe thresholds, ensuring compliance with CE and ISO22000:2025 standards.

Energy-Saving Workflow

- Loading & Preparation: Arrange products evenly on corrosion-resistant trays.

- Program Selection: Choose presets (e.g., “Herb Low-Temp” or “Fruit Medium-Temp”) or customize parameters.

- Heat Recovery Activation: The system recycles thermal energy from previous cycles to preheat incoming air.

- Dynamic Adjustment: Sensors adjust airflow and temperature based on real-time moisture levels, optimizing energy use.

- Quality Output: Achieve target moisture content (e.g., <8% for herbs, <12% for fruits) with minimal nutrient loss.

Market Advantages

- Rapid ROI

• 50–70% Energy Savings: Payback achieved in 12–18 months for high-volume operations, supported by reduced grid dependency through optional solar integration. - Versatility

• Multi-Industry Use: Process rose petals for cosmetics, herbs for functional teas, or fruits for retail snacks. - Global Compliance

• Certified for CE, ISO22000:2025, and FDA 21 CFR Part 117, ensuring access to EU, North American, and Asian markets.

Success Stories

- Organic Herb Farm in France

A Provence-based facility reduced drying costs by 60% while preserving 90% of essential oils in lavender and rosemary, supplying luxury skincare brands. - Tropical Fruit Cooperative in Thailand

A mango processing plant cut energy use by 55% and achieved ISO22000 certification, exporting freeze-dried products to European supermarkets. - Rose Petal Valorization in Bulgaria

A cosmetics manufacturer optimized volatile oil retention in rose petals, boosting product value by 30% for the $50 billion global beauty market.

Technical Specifications

• Temperature Range: 25–80°C

• Capacity: 150 kg–12 tons/day (modular)

• Certifications: CE, ISO22000:2025, FDA

• Warranty: 12-month comprehensive + lifetime technical support

Why Choose MeiYa ProDry 2025?

• Proven Sustainability: Aligns with EU Green Deal 2030 targets for industrial energy efficiency.

• Smart Scalability: Modular design supports SMEs to large-scale processors.

Transform Perishables into Premium, Shelf-Stable Products

From antioxidant-rich fruits to aromatic rose extracts, MeiYa’s dehydrator delivers unmatched efficiency and quality.

Contact us today for a free energy-saving analysis or customized drying trial!

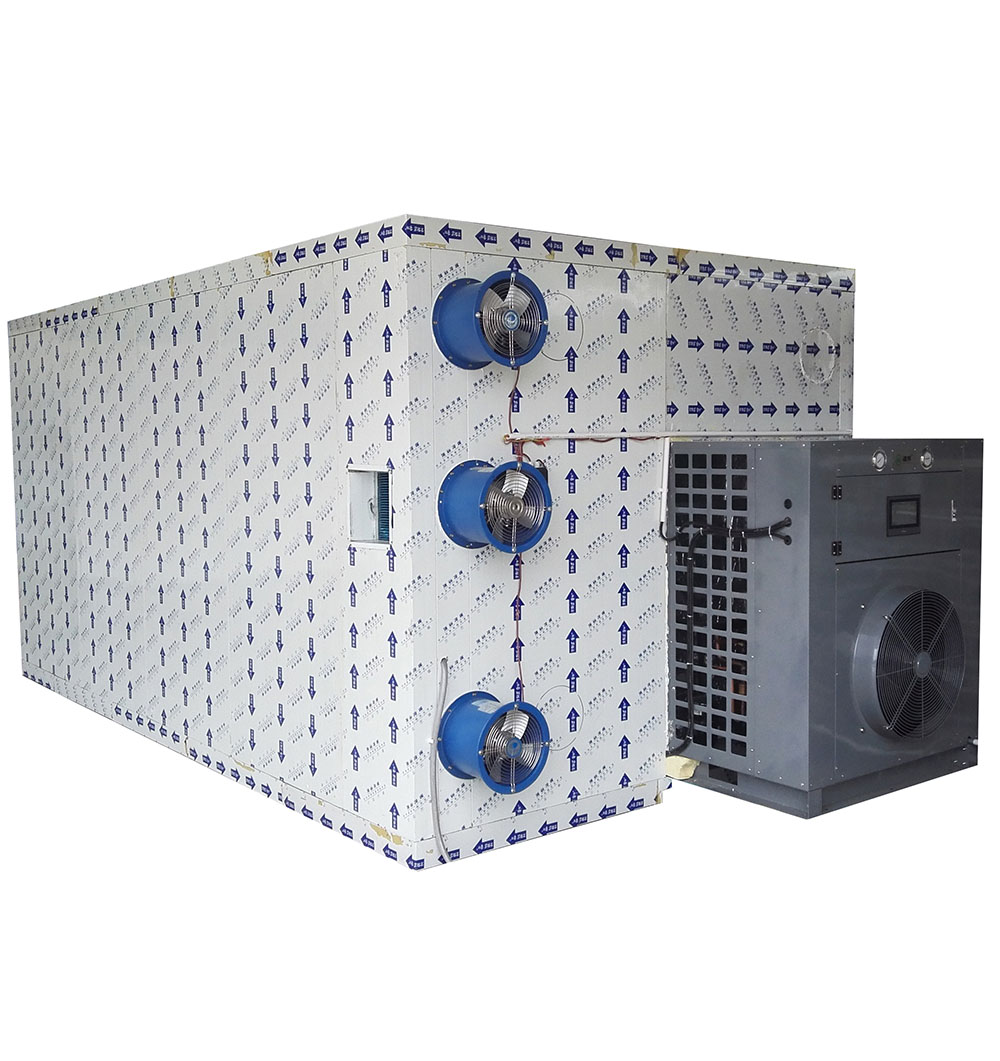

MeiYa Heat Pump Dryer Machine

- No MOQ & Customization Unlimited

- Drying + Dehumidify + Cooling

- PLC + Touch Screen Control

- 7-10 Days Delivery Time

Parameter:

| Single dryer+drying chamber | ||||

| Model | Unit | MY-03RD | MY-06RD | MY-12RD |

| Power input | KW | 5.5 | 9.5 | 19.4 |

| power supply | V/PH/HZ | 380V/3PH,50/60HZ | 380V/3PH,50/60HZ | |

| 220V/1PH,50/60HZ | ||||

| Rated current | A | 9.6A(380V),22A(220V) | 17.0 | 30.0 |

| Heating capacity | KW | 10.5 | 21.0 | 42.0 |

| Cooling capacity | KW | 7.8 | 18.0 | 32.0 |

| Dehumidity | L/H | 12.0 | 25.0 | 50.0 |

| Max temperature | ℃ | ≤75 | ≤75 | ≤75 |

| Working condition | ℃ | 0-43 | 0-43 | 0-43 |

| Electric shock protection grade | 1 | 1 | 1 | |

| Max exhause pressure | M(P)a | 30 | 30 | 30 |

| Noise | d(B(A | 75 | 75 | 75 |

| Power consumption/H | KWH | 4.8 | 8.5 | 15.0 |

| Electric heater | KW | 3.0 | 6.0 | 12.0 |

| Blowing type | / | HORIZONTAL BLOWING TYPE | ||

| Demsnssion of dryer | MM | 3160*2070*2200 | 5700*2170*2200 | 5810*3230*2200 |

| Weight | KG | 180 | 285 | 480 |

Buying Guiding:

Recommend drying machine+Drying chamber sizes

| ITEM | DESCRIPTION | PRODUCT CAPACITY | DRYING CHAMBER SIZE |

| 1 | One unit MY-03RD+Drying chamer | 300/batch | 4000*2000*2200 |

| 2 | One unit MY-06RD+Drying chamer | 600/batch | 6000*2800*2200 |

| 3 | One unit MY-12RD+Drying chamer | 1300/batch | 6000*3000*2200 |

| 4 | Two unit MY-03RD+Drying chamer | 1200/batch | 7000*2200*2200 |

| 5 | Two unit MY-06RD+Drying chamer | 1500/batch | 10000*2800*2200 |

| 6 | Two unit MY-12RD+Drying chamer | 3500/batch | 10000*3000*2200 |

Our Projects:

Our Factory:

Production Processing:

Drying Machine Components:

Standard Working Modes:

- Typically 3 modes available:

- Drying Only

- Rapid temperature rise; unable to discharge moist air

- Drying + Dehumidify

- Chamber temperature rises while discharging moist air

- Cooling

- Temperature can drop to 10°C (minimum)

- Important Note:

- If temperature control becomes unstable, switch to Temperature & Humidity Mode.

- Drying Only

Drying Machine Common Issues

- Q1: High Pressure Protection

- A1.1: Hot air circulation system failure

- AC contactor overload protection

- (Check phase loss/loose terminals/voltage instability)

- Partial fan failures

- (Verify switches configuration and burnt components)

- Mechanical fan damage

- (Replacement or removal required)

- AC contactor overload protection

- A1.2: Tray overloading phenomenon

- Optimal spacing: 8-10cm between trays

- (Causes airflow obstruction in drying chamber)

- Optimal spacing: 8-10cm between trays

- A1.3: Electronic expansion valve anomalies ▪ Automatic minimum aperture adjustment

- (Sensor calibration: Reposition or exchange Sensor 1/2) ▪ Valve body malfunction

- (Manual rotation intervention needed)

- (Sensor calibration: Reposition or exchange Sensor 1/2) ▪ Valve body malfunction

- A1.4: Chamber overheating condition

- (Temperature parameter adjustment solution)

- A1.5: Refrigerant specification error

- (High-temperature type gas recharge required)

- A1.1: Hot air circulation system failure

- Q2: Low Pressure Protection

- A2.1: Gas leakage scenario

- (Leak detection and repair protocol)

- A2.2: Extreme cold environment

- (Extended check intervals or R22/R417A refill)

- A2.3: Valve aperture deficiency

- (Expansion valve opening adjustment method)

- A2.1: Gas leakage scenario

- Q3: Exhaust Temperature Overload

- A3.1: Gas leakage recurrence

- (Refers to Q2.1 resolution process)

- A3.2: Valve operational failure

- (See A1.3.2 corrective action)

- A3.1: Gas leakage recurrence

- Q4: Sensor Malfunction

- A4.1: Temperature sensor defect

- (Replacement procedure guidelines)

- A4.1: Temperature sensor defect

- Q5: Moisture Evacuation Failure

- A5.1: Dehumidification fan damage

- A5.2: Control system malfunction

- A5.3: Power delivery irregularity

Our Services

A. Payment Service

- T/T (Telegraphic Transfer)

• Applicable to all transaction types. - L/C (Letter of Credit)

• Exclusively available for container orders. - Western Union

• Recommended for sample orders and spare parts procurement.

B. Technical Service

- Capacity Analysis & Model Recommendation

• We provide customized capacity calculations and optimal model selections based on operational requirements. - Professional Technical Support

• Comprehensive refrigeration and electronic engineering assistance for installation, debugging, and system operation. - Spare Parts & Post-Warranty Support

• Genuine spare parts and technical guidance provided during and after the warranty period. - Training Programs

• On-site or factory-based training courses available upon request.

C. After-Sales Service

- Technical Assistance

• Continuous support for installation, operation, and maintenance. - Warranty Policy

• 12-month warranty coverage with optional extension. - Cost-Effective Post-Warranty Support

• Spare parts and technical services offered at competitive rates after warranty expiration.